Senior Design Project: SiPhox, Inc.

In the BioEngine Senior Design Program at the University of California, Irvine offered both Material Science & Engineering and Biomedical Engineering majors, I chose to follow the industry path offered to be partnered with a participating company. Following my group's formation, we were then given the opportunity to work alongside SiPhox, Inc. focused on developing an at-home diagnostic system curated for the COVID-19 pandemic. My group had connected with their CCO, Michael Dubrovsky, and was tasked to design a working prototype of a mass testing device to check and reinforce SiPhox's device results are accurate readings.

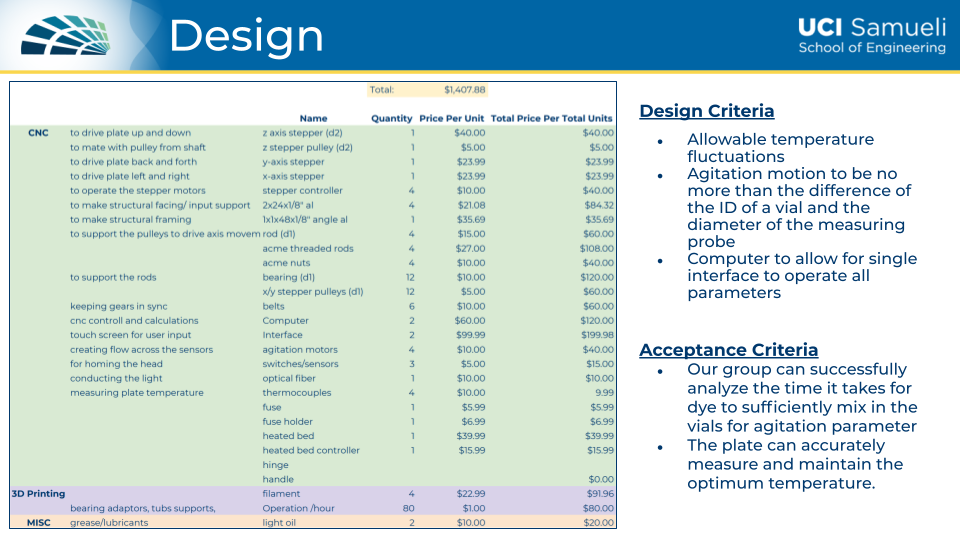

Before designing our prototype, my team and I researched similar products already on the market and analyzed what each machine offered to compete with. The main companies we found were ForteBio's Octet RED96 System & Opentron's Temperature Module GEN2. This set up our project to create a highly competitive device both physically and financially against these products.

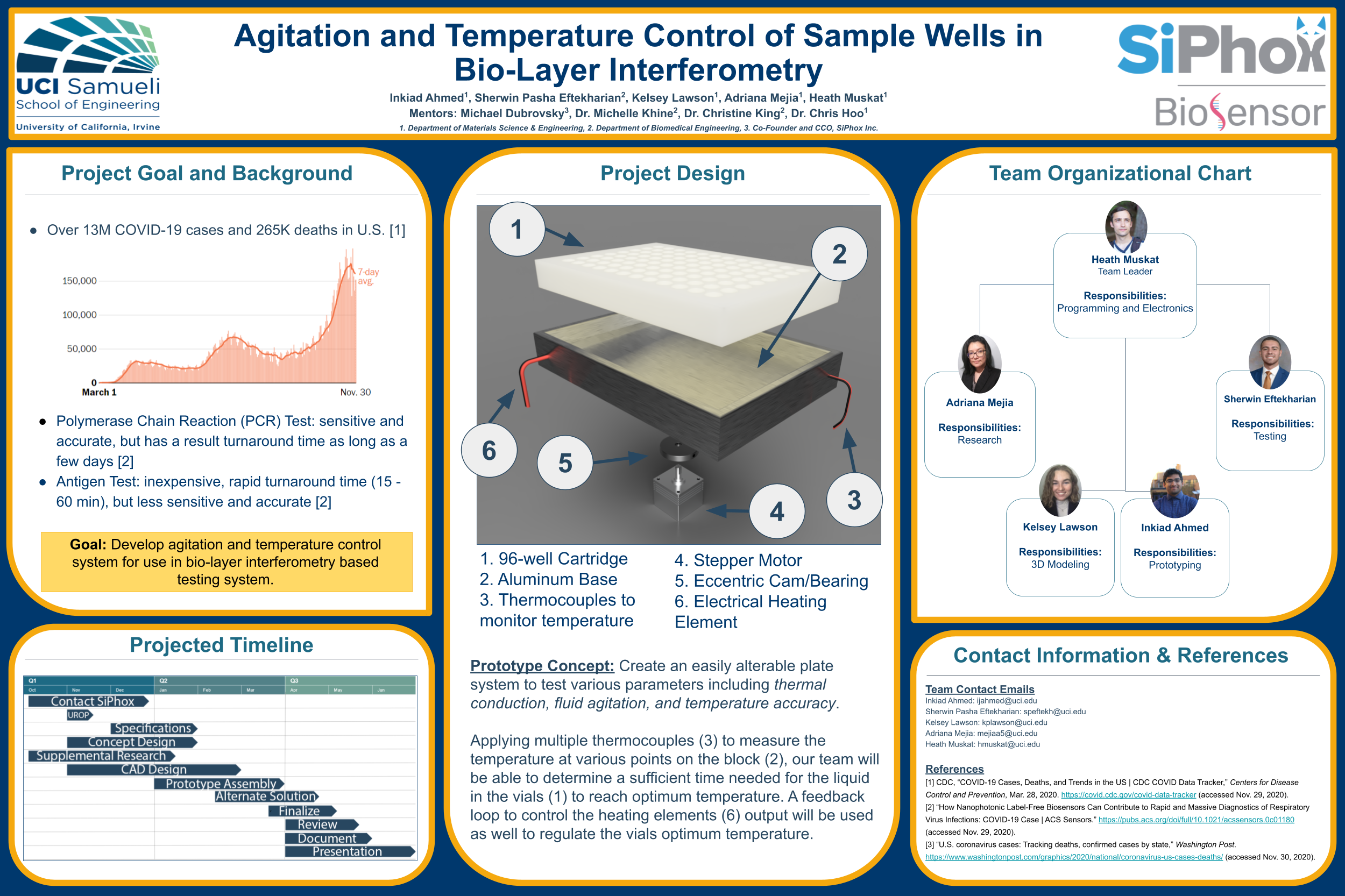

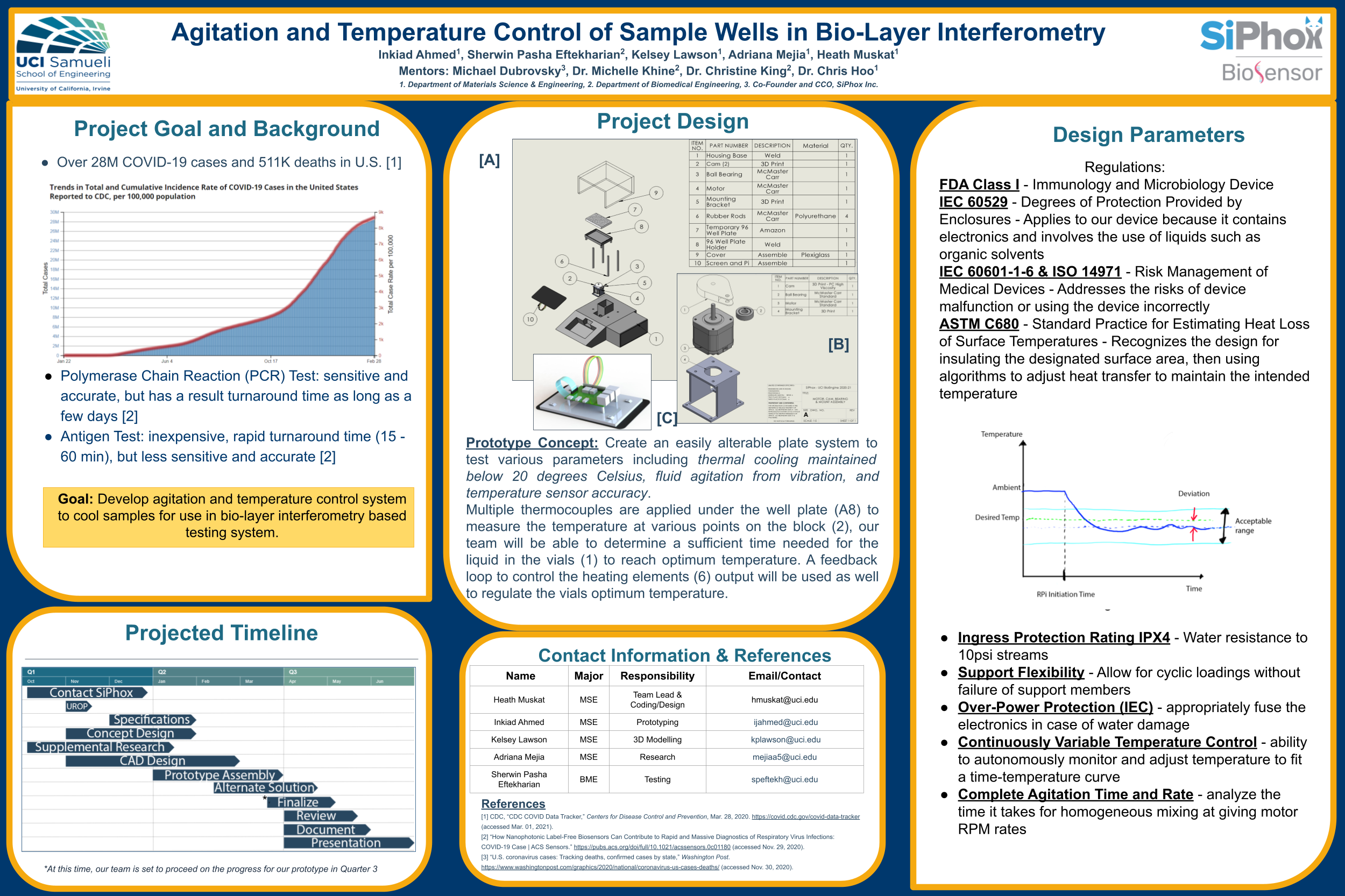

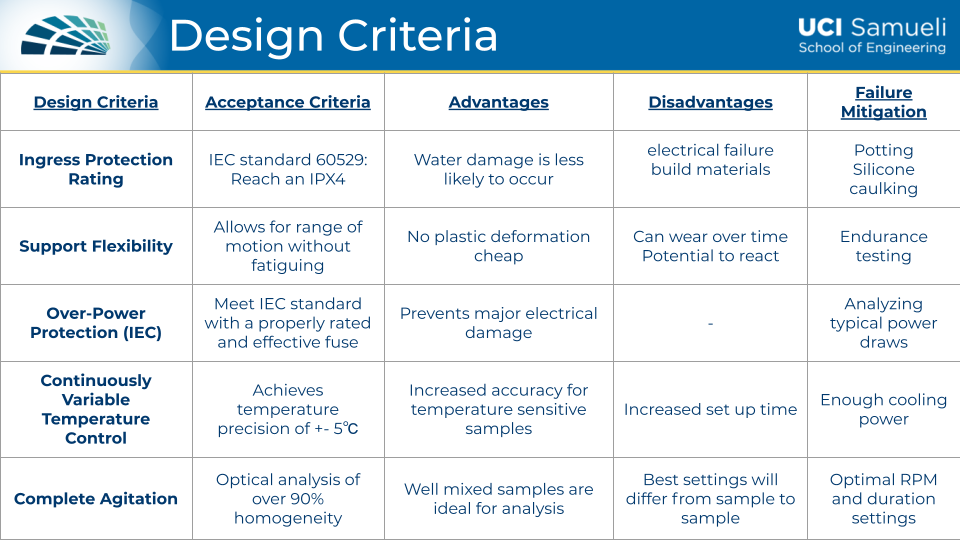

The physical components required by Michael were to design an easily alterable prototype to test various biological parameters through thermal conduction, fluid agitation, and temperature accuracy. The idea was that our prototype design is the first phase of the device and would eventually undergo more complex parameters such as adding bio-layer interferometry (BLI) to correctly analyze the biological samples. This first quarter of researching and figuring out our design approach is shown in my teams’ first poster and presentation below.

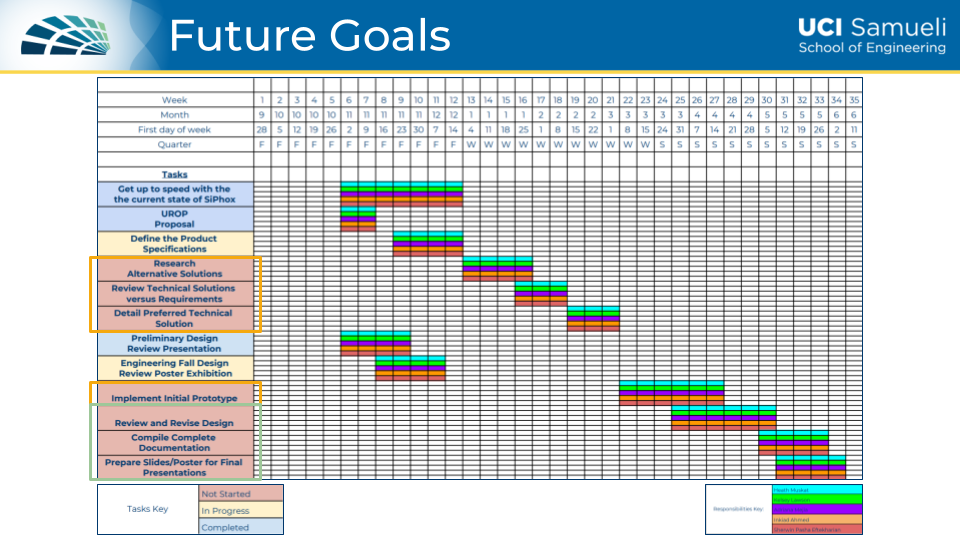

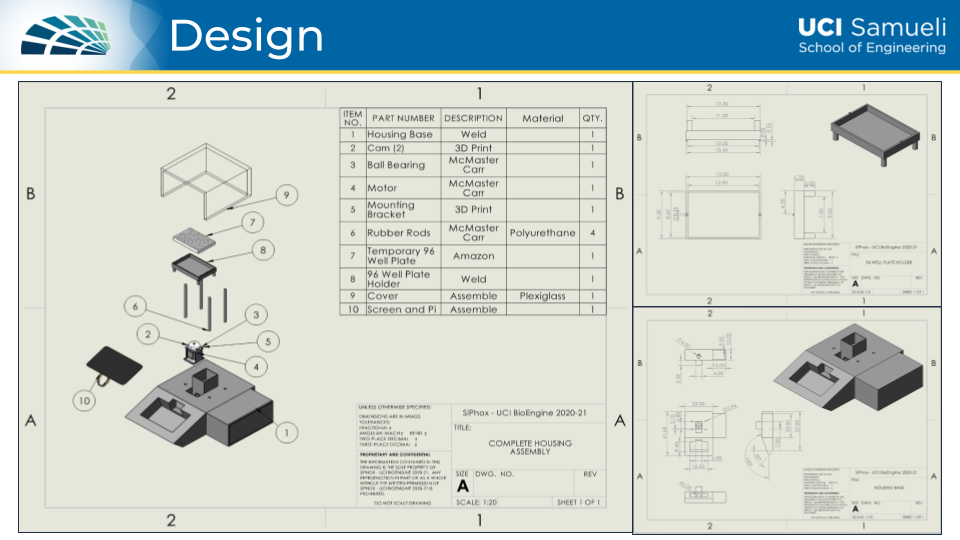

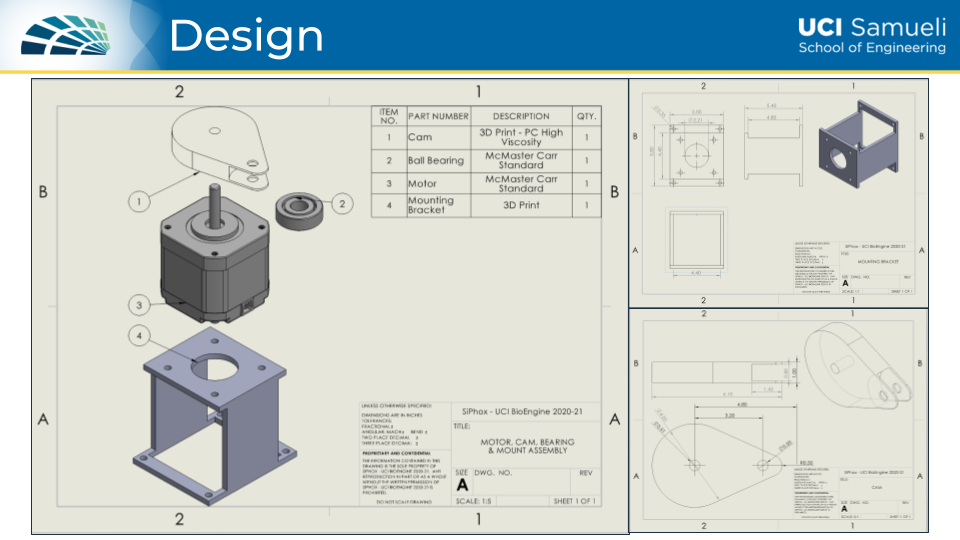

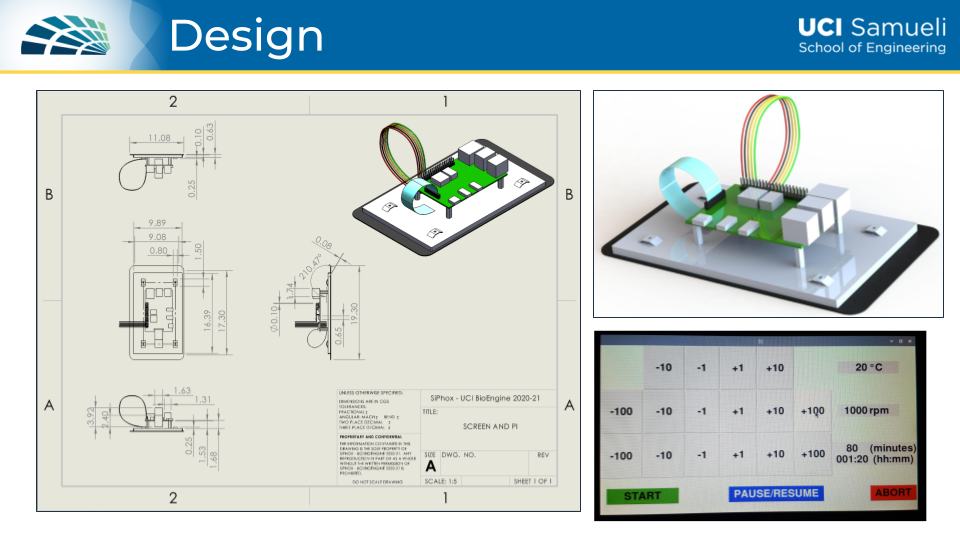

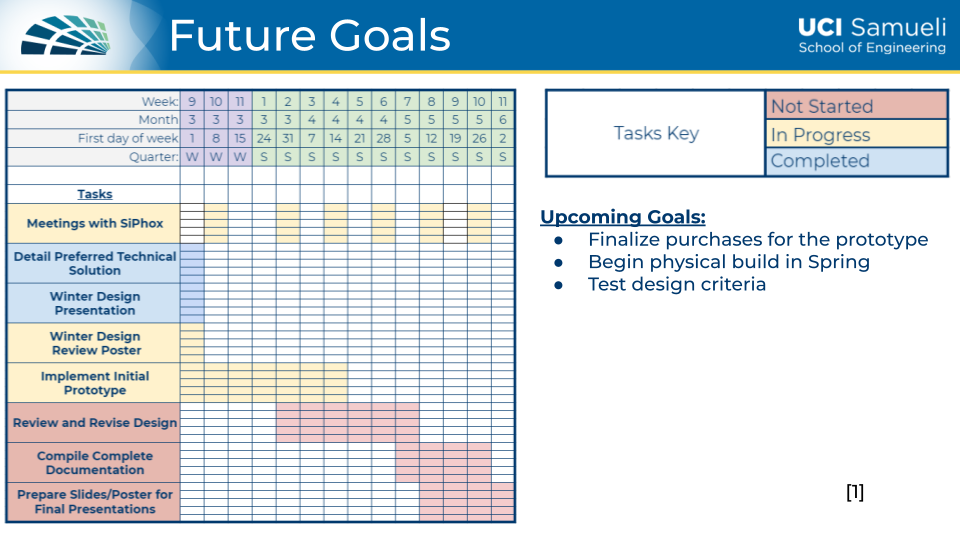

Throughout Winter Quarter I was responsible for completing the 3D model of the entire chassis and subcomponents using SolidWorks. I had also designed and updated our website about our intentions working alongside SiPhox. Our design concept is seen in our second poster below. The goal we had set up was to start building our prototype by the end of the quarter. However, due to processing and shipping delays, all of the parts ended up coming late. This pushed our deadline to assemble the prototype late into Spring Quarter.

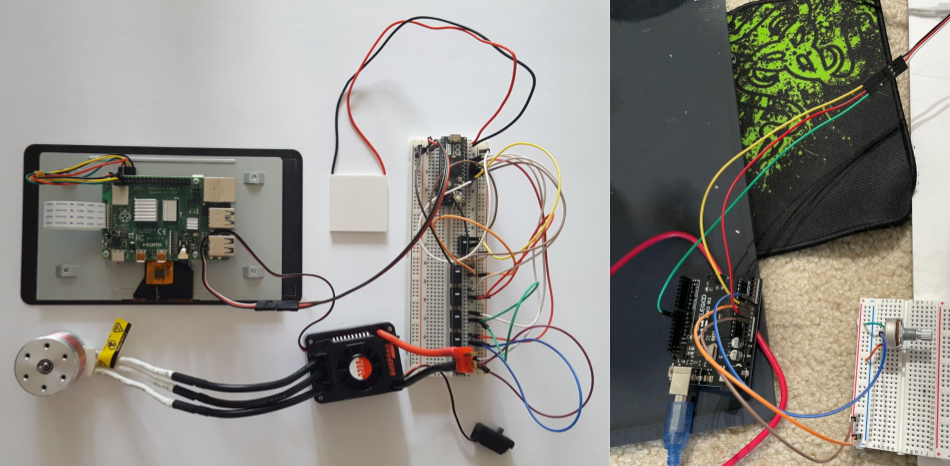

Although my team and I had unforseen delays in the delivery of the parts, we were able to refocus our work into coding the electronic components. Heath, my team leader, was working on the interface and temperature control whereas I got to test and code the motor component. This was a challenge for me at first because Heath was using Python for the interface and wanted me to code the motor in Python as well. This was difficult becasue I couldn't test my code because I only had an Arduino Uno board at my house. So instead, I used an Arduino Uno that I had and used a potentiometer for controlling the speed so I could test the motor without the control panel.

The last week of the quarter my team and I could finally meet up together in person to combine the components and finish building the chassis. The end prototype is shown below. My team also presented our work at UROP.

Spring Quarter Presentation for UROP

Spring Quarter Final Report