Fundamentals of Material Processing: Lithium Ion Batteries

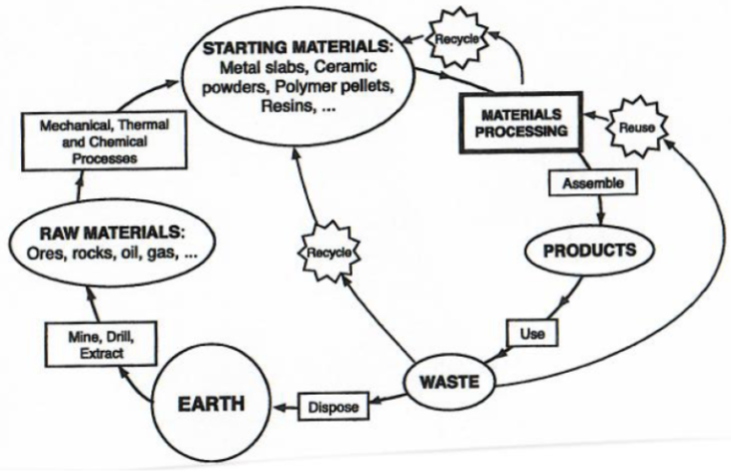

UCI offered engineering elective courses that changed content and professors every quarter. During my Winter Quarter in 2020, Professor Apelian created a course on the Fundamentals of Material Processing focused on answering the question: How are materials processed to make things? The objective of this course was to provide in-depth knowledge of manufacturing processes on how to make components/things out of materials applying to the three main classes of engineering materials: metals, ceramics, and polymers.

Beyond the traditional lecturing methods, the class was split up into groups and we were allowed to find a topic to dissect and present on how it is manufactured. For my group, we had focused on Lithium-Ion Batteries for Small Electronics. We were able to split up our presentation so that each group member could research and present their subtopic. I was responsible for addressing the second part of the manufacturing method of how Lithium is extracted and what it undergoes to be used for electronics. This framework outline was submitted to our professor to be reviewed before finalizing our slides. The main recommendation our group got was to maintain the audience’s attention by keeping track of where we are in the slides through a table of contents as well as to not overly complicate the manufacturing terms.

Project Outline with Team Responsibilities

Taking these notes from our framework I had formatted my slides to be concentrated on the images of the manufacturing processes instead of relying on only text. Below is a run-through of my slides where I would discuss each numbered section. This had forced me to practice my speaking skills since the majority of the information was spoken instead of written, so the audience would need to understand and follow me when I spoke. I had met with my professor outside of class alongside my group for a practice run of our presentation. Because of this extra step, we had received more recommendations now concentrating on how we presented as a group. Although my slides were good, Professor Apelian had suggested that I did not skim too much of the manufacturing steps and that it would be beneficial to take my time to break it down. I made sure to practice this before our official presentation day.

In the end, this class exposed me to industry-level standards expected with materials testing and processing but also challenged my presentation skills. I can relay the information I've researched into a more comprehensible summary. This benefits both my audience members and myself since it involves me understanding the information instead of rambling off research-level diction. Moreover, I've been introduced to melting, solid-state, powder, dispersion, solution, and vapor processing methods of starting materials. This was followed by quality control and non-destructive testing and evaluations of the materials. Being introduced to these common practices allows me to recognize these methods in industrial applications and increase my knowledge.