Lab Courses & Undergraduate Research Experience

LAB COURSES: MATERIAL CALCULATIONS, ANALYSIS, & TESTING

April 2019 - March 2021

DIFFUSION AND HEAT TRANSPORT IN MATERIALS

APRIL 2019 - JUNE 2019

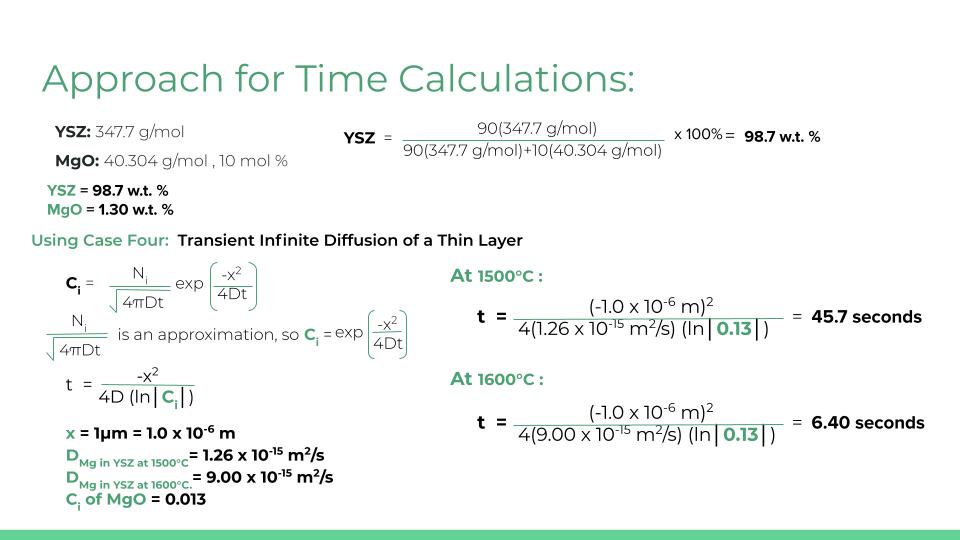

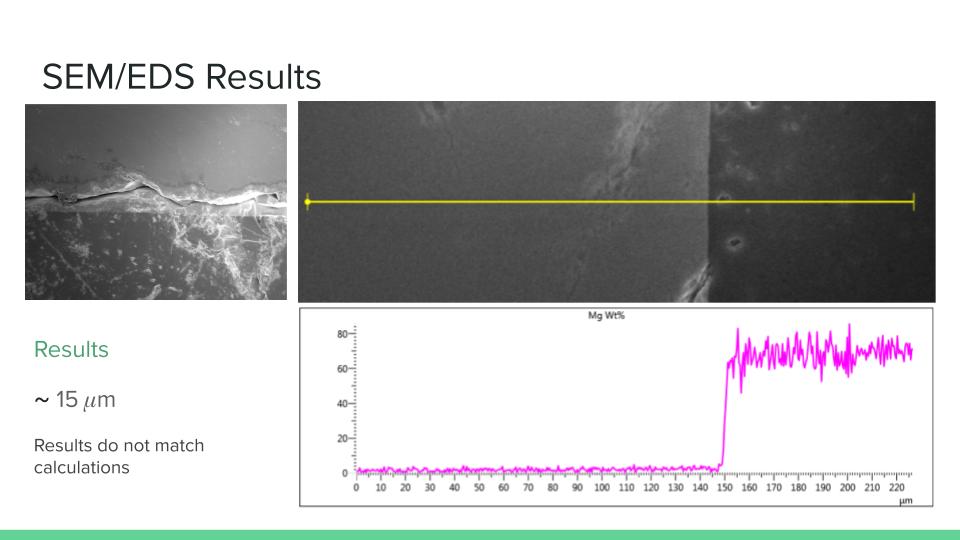

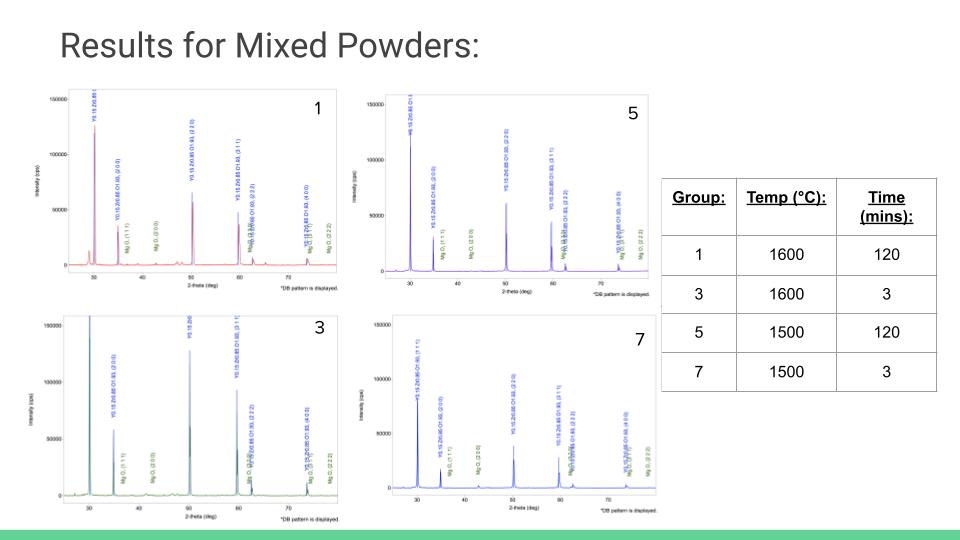

Starting my sophomore year of college, my courses started to align theoretical calculations with physical experiments. The first class introducing me to this concept was in Diffusion and Heat Transport in Materials where I examined how kinetics affected materials development, behavior, and processing. This course highlighted how kinetics and diffusion are key to designing materials processing and heat-treating strategies. To demonstrate this, 3 of my classmates and I had presented this concept through the example of grain boundary diffusion of magnesium into yttria-stabilized zirconia, a ceramic material. The purpose of this experiment was to see how accurate our calculations were in predicting how much time was needed to completely dissolve the magnesium oxide into yttria-stabilized zirconia in a mixed powder solution at constant temperatures. I was able to mix the powders and press them into a solid pellet ready for heat treatment. My team and I then compared our calculations from the results from the lab which is shown below after being analyzed using scanning electron microscopy (SEM) and energy-dispersive x-ray spectroscopy (EDS) and then x-ray diffraction.

Upon receiving these results, my team and I compared them to our theoretical calculations of the time we expect to see the diffusion start in the samples. As you can see, my team had also made these calculations under the assumption that our sample will behave similarly to the case for transient infinite diffusion of a thin layer. Using these theoretical times with the known temperatures, we then estimated the distance where we should start to see diffusion in the samples. However, based on our comparisons from the lab, our results did not match. This means we could try again using a different case to assume our new calculations. From this presentation, I got to experience how assumptions during theoretical calculations affect the interpretation when compared to physical results. I can now recognize where I can adjust my calculations to follow the experiment and learn from my mistakes.

MECHANICAL OF STRUCTURES LAB

SEPTEMBER 2019 - DECEMBER 2019

Following this class, I was then enrolled in a Mechanical of Structures lab that focused on the experimental techniques for the measurement of mechanical properties of materials and structures. The methods I followed were for load, displacement, and strain measurements. During the lab session, I performed tensile, bending, compression tests to determine the strength, stiffness, and toughness for metals, polymers, ceramics, and composites until the structures deformed.

This lab course was a mechanical course and had taught me to expand my knowledge in coding thermal settings for an Arduino Uno and proper introductory soldering methods. I also got to get hands-on experience for tension and bending tests that I have been theoretically calculating during lectures. Below are the lab reports my group and I have completed in the course. I was responsible for recording and compiling the results as well as add any calculations needed.

Report 1: Thermistor Response and Thermal Contraction

Report 2: Tension and Bending Testing

Report 3: Pressure Vessel Test

MECHANICAL BEHAVIOR LAB

APRIL 2020 - JUNE 2020

Similar to the 'Mechanical of Structures' lab, I had a Mechanical Behavior lab that continued to introduce me to experimental techniques to characterize mechanical properties of materials. There was an emphasis on correlations between properties and microstructures shown through experiments including plastic stability in tension, the effect of grain size on flow stress, microstructural engineering.

This lab course was the first session run under in-person restrictions during the pandemic. This means the course’s structure had changed from in-person experimentation to referring to research papers. Based on this format, I reinforced my skill in finding relevant research regarding our topics. These lab reports were also written in a group setting so establishing a team schedule for collecting our papers then distributing the sections was a necessity. I was responsible for writing the abstracts, introductions, inputting the results, and addressing the discussion questions.

Report 1: Analysis of Ductile to Brittle Transition Temperature

Report 2: Analysis of Linear & Viscoelastic Materials Using the Compression Test

Report 3: Optical Metallographic Analysis of Steels Microstructure

Report 4: Tensile Test Analysis

Report 5: Hardness Test Analysis

X-RAY DIFFRACTION, ELECTRON MICROSCOPY, AND MICROANALYSIS LAB

APRIL 2020 - JUNE 2020

Alongside the previous lab, I had also taken an X-ray Diffraction, Electron Microscopy, and Microanalysis lab that introduced me to physical material characterization using X-ray diffraction (XRD) and scanning electron microscopy (SEM). This course included topics on using XRD for analysis and SEM imaging and microanalysis.

This was the second lab course that I had taken at the beginning of the pandemic, hence the traditional way the lab is taught had changed format. My Professor had decided that it would be most beneficial to watch YouTube videos about the XRD and SEM machines and then answer specific questions instead of a group lab report. Therefore, my write-ups to the desired questions are linked below. Based on this new lab format, I had found it was easier to refer back to the steps of turning on or adding the sample to the machine setups. This strengthened my understanding of how these machines work and how I can adapt to unexpected changes.

Lab 1: Introduction to X-Ray Diffraction

Lab 2: XRD, Electron Microscopy, & Microanalysis

Lab 3: Scanning Electron Microscopy (SEM)

Lab 4: SEM, EDS, TEM

Additionally, for our final, we were assigned to write a report that focuses on a real-world application that uses these characterization techniques. I was interested in 3D printed prosthetics especially since I had worked on a 3D printed prototype the previous quarter. Within the structure of the report, we were required to find 3 research papers that used either technique and why it was needed and what effect did it have in concluding the experiments.

Final Report: Analysis of 3D Printed Prosthetics Using XRD & SEM Techniques

SYNTHESIS AND CHARACTERIZATION OF MATERIALS

JANUARY 2021 - MARCH 2021

Finally, during my senior year, I took a laboratory course in Synthesis and Characterization of Materials focusing particularly on ceramic, polymer, and semiconductor materials. I am able to connect the process, structure, properties, and performance to materials science knowledge in a lab setting despite this course being taught remotely. However, the virtual lectures increased my ability to research and reference credible sources to support my findings in my group lab reports.

Lab 1: PAN/PVA Nanofiber Electrospinning Fabrication and Post-annealing

Lab 2: Bioinspired Magnetite Coprecipitation Synthesis with Polyacrylic Acid (PAA)

Lab 3: Sol-Gel & Solution Combustion Synthesis (SCS) for Ce-Doped CaO

Lab 4: Characterization of Perovskite La0.8Sr0.2MnO3 (LSM82) & Electrical Measurement of Semiconductors

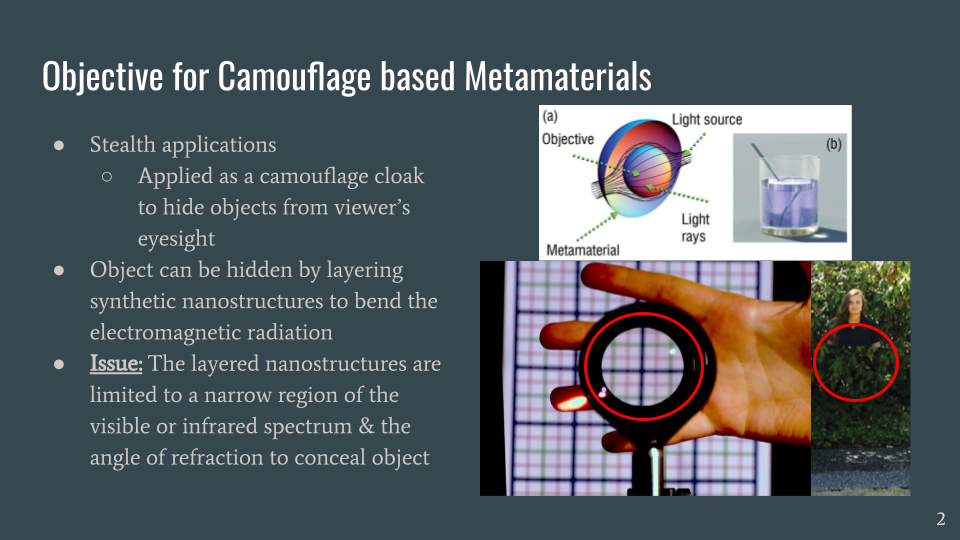

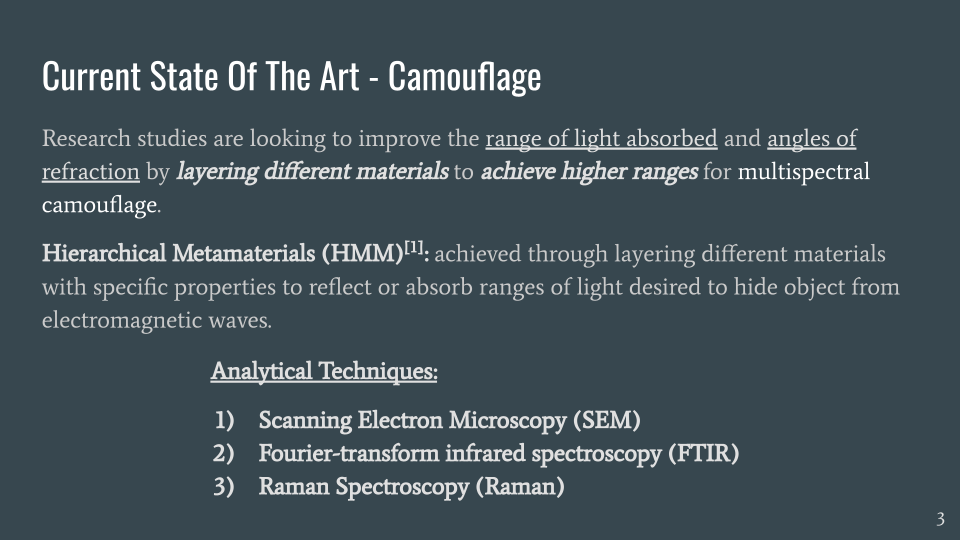

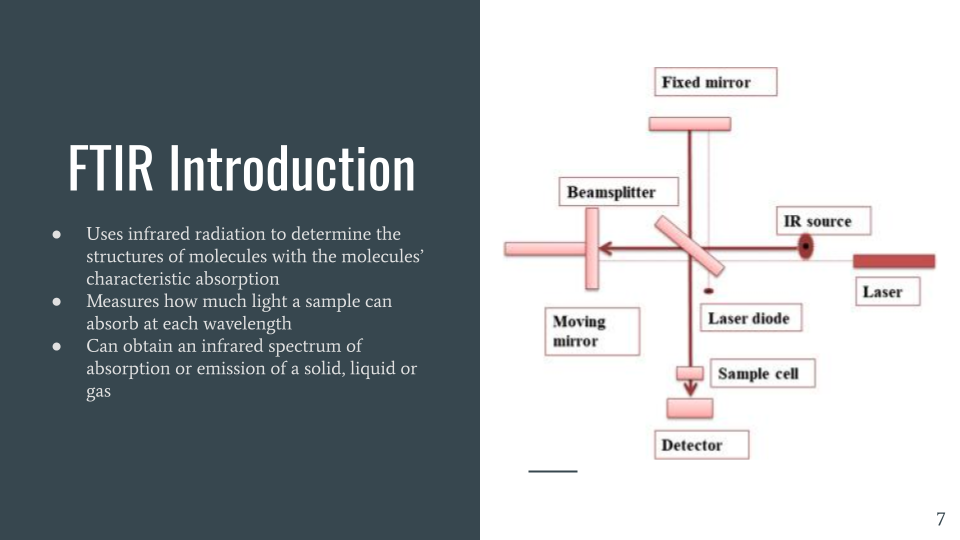

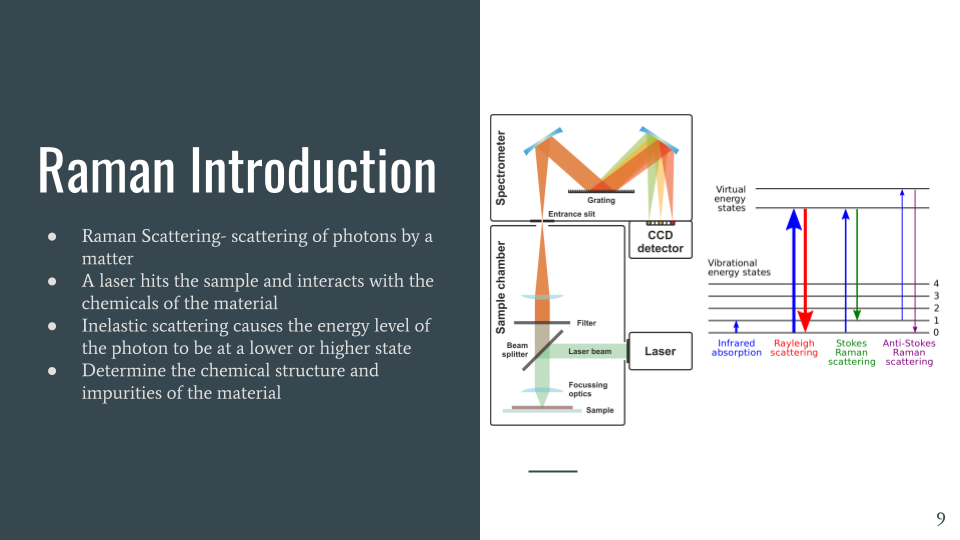

The last part of this course was to select a topic on a material discovery and relate the material synthesis to what we learned in class. From the topics listed, my group and I were interested in Metamaterials and how they can be used as complex camouflage. I had presented the slides introducing the concept of what a metamaterial is and how we can use this for camouflage. My tactic was to intrigue my peers by relating what they know already to then increase its complexity that is seen during the rest of the presentation.

Final Presentation on Camouflage Metamaterials

UNDERGRADUATE RESEARCH: BIOMIMETICS & BIOMATERIALS RESEARCH LAB

January 2020 - February 2020

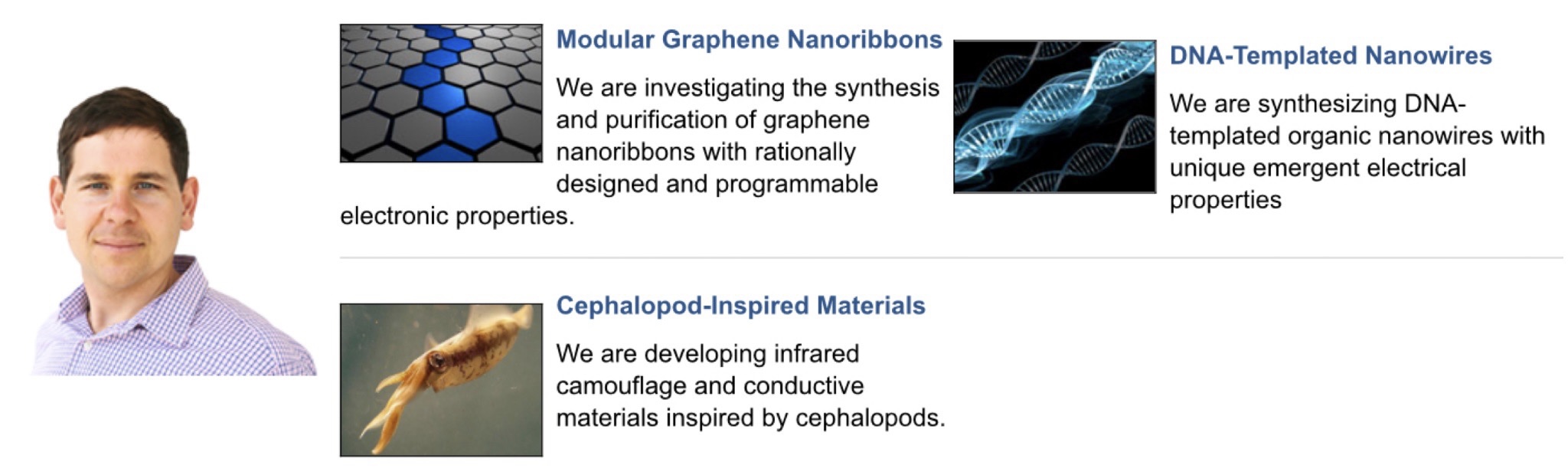

During my time attending the University of California, Irvine, I started to narrow down my interests within the subject of Materials Science since it is such a vast topic. To figure out what is offered, I joined the Materials Science Club at UCI during my first year and maintained these relationships throughout college. Over time, members within the club recommended getting more in-depth hands-on experience by joining research labs offered by Professors. Taking this advice I had emailed Professor Gorodetsky who specializes in Biomolecular and Chemical Engineering with a focus on Materials Science applications.

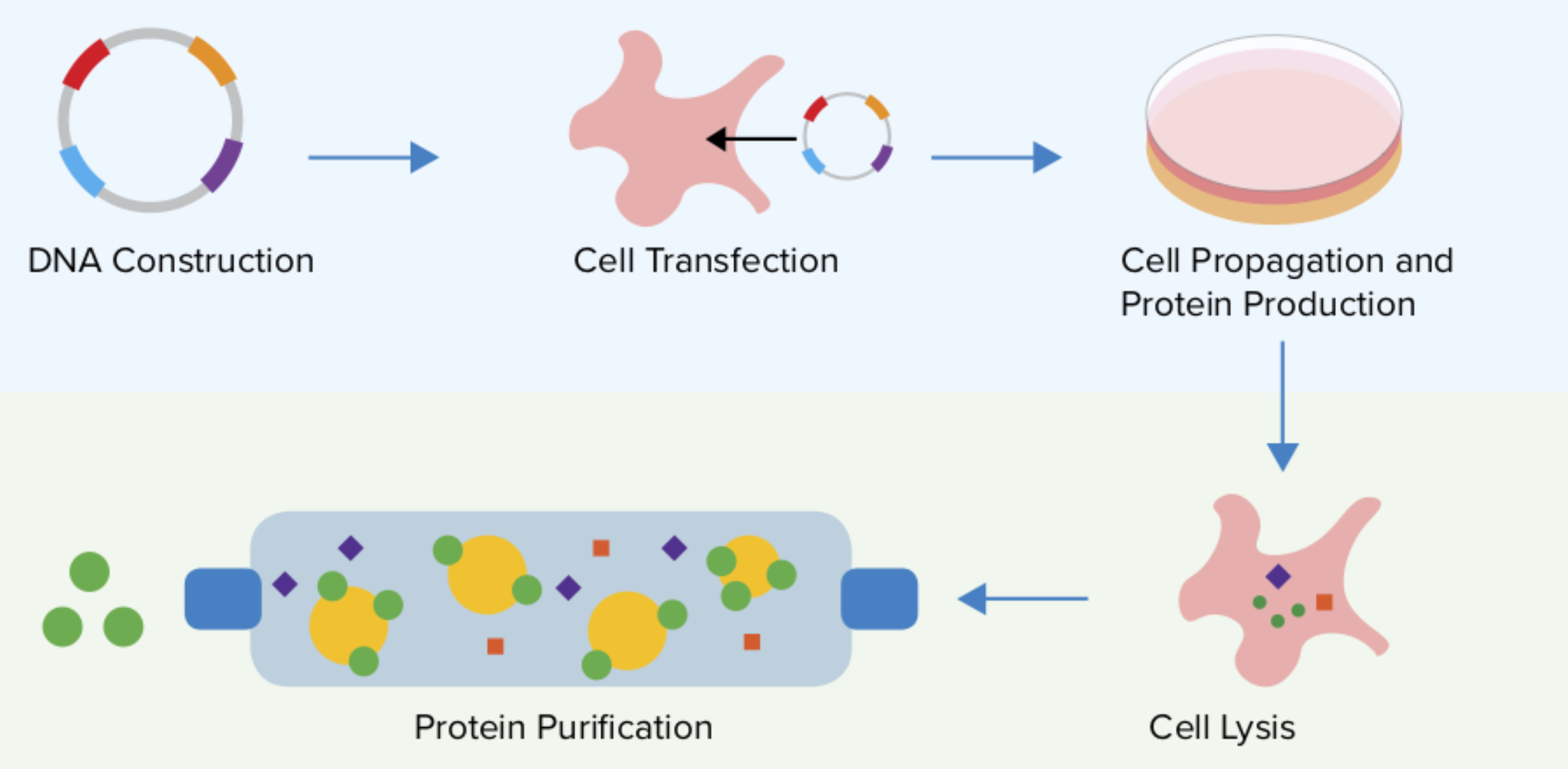

Gorodetsky's Group for Biomolecular Electronics focused on three main interests: 1) Modular Graphene Nanoribbons, 2) DNA-Templated Nanowires, and 3) Cephalopod-Inspired Materials. All of the graduate students involved with these topics needed synthesized bacteria proteins to then run their experiments. Therefore, as an undergraduate research assistant, it was my duty to support the graduate students by organizing and tracking their supplies. This means I was responsible for making the starter cultures and media prep, expression, lysis and inclusion body prep, filtration, and concentration of inclusion body for HPLC, HPLC, and lyophilization.

In the end, my duration to contribute towards this research was cut short from the pandemic putting a halt in faculty research. However, throughout my time in the lab, I strengthened my skills in data collection and note-taking for finalizing my reports and presentations. Before going into the laboratory space, I was also required to review research papers on the topics of protein expression and demonstrate my knowledge to my lab mentor Nikhil Kaimal. Reviewing these papers by actively annotating the margins helped me reference important steps back to Nikhil. Moreover, because I was a new addition to the lab group, I got to work with multiple students to teach me what I would be doing in the lab and the expectations that follow. This opportunity to ask questions and ensure I was thorough in my data collection reinforced my skills.